Quality Assurance and Quality Control of Pharmaceutical Botulinum Toxin A

Introduction: Botulinum Toxin (BoNT) is one of the most toxic substances known to man. Botox is approved by U.S. Food and Drug Administration for treating neuromuscular ailments such as excessive sweating, migraines, overactive bladder, muscle disorders, and ophthalmologic disorders. Due to its lethality even as low doses, ensuring product quality and safety is important to prevent adverse events and potential death. The Mouse Bioassay is the current gold standard method used to assess quality control and assurance for BoNT/A, however, it has several limitations. This in vivo method requires an intraperitoneal injection of toxin extract directly into a mouse to establish the lethal dose and the biological activity. The lethal dose is defined as the amount of toxin that kills 50% the mouse cohort. Unfortunately, a large sample volume is necessary to carry out this procedure.5,6 At least 100 mice are required to determine lethality dose of a single BoNT lot (10 BoNT dilutions for groups of 10 mice) which can be seen as unethical. Another disadvantage of this procedure is assay time. It usually takes several days to complete and requires 12 hours to produce 1 LD50/ml of BoNT/A. Other limitations include cost, special animal facility requirements, and potential hazards associated with injections. Furthermore, different mouse species show different sensitivity to BoNT, and potency units of BoNT have not been standardized among manufacturers.8 With the growing market and high demand for both therapeutic use and cosmetic use, it is important to provide an efficient method to evaluate quality control and assurance of the toxin. Therefore, mouse bioassay is unfavorable in terms of its limitations. Fluoroimmunoassay is used in this experiment to address the limitations of mouse bioassay. This method is more rapid, flexible, sensitive, and ethical compared to the mouse bioassay.

Objectives: Using analytical fluoroimmunoassay to detect, and quantify the concentration of BoNT/A heavy chain and to demonstrate the efficacy of immobilized anti-BoNT/A antibody (6B2-2) at capturing BoNT/A heavy chain.

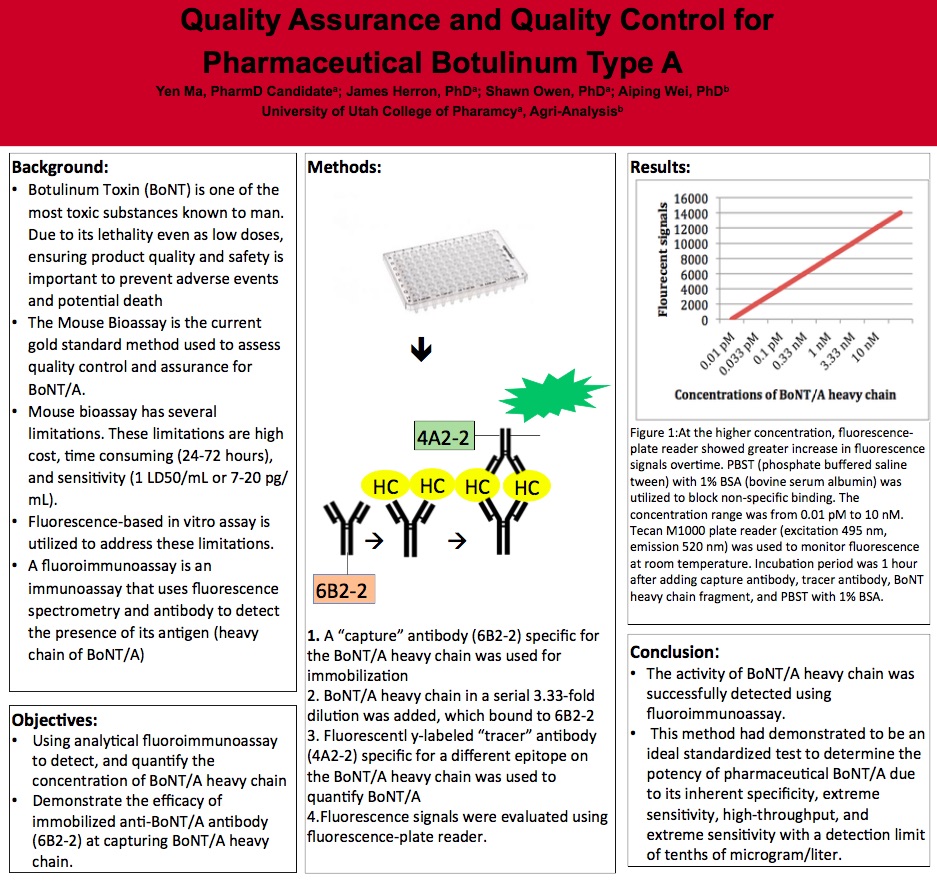

Methods: The concentration of BoNT/A heavy chain was determined using a sandwich immunoassay in which a “capture” antibody (6B2-2) specific for the BoNT/A heavy chain was immobilized by physical adsorption to the wells of a microtiter plate and a fluorescently-labeled “tracer” antibody (4A2-2) specific for a different epitope on the BoNT/A heavy chain was used to quantify BoNT/A binding to immobilized capture antibody. Fluorescence signals were evaluated using fluorescence-plate reader.

Results: The activity of BoNT/A heavy chain was detected using fluorescent-labeled tracer antibody (4A2-2). As the concentration of BoNT/A heavy chain increases, the fluorescence signals increase as well. Immobolized BoNT/A antibody (6B2-2) also showed a high affinity to BoNT/A.

Conclusion: The activity of BoNT/A heavy chain was successfully detected using fluoroimmunoassay. This method had demonstrated to be an ideal standardized test to determine the potency of pharmaceutical BoNT/A due to its inherent specificity, extreme sensitivity, high-throughput, and extreme sensitivity with a detection limit of tenths of microgram/liter.

Published in College of Pharmacy, Virtual Poster Session Spring 2020

Nice work! It does seem preferable to not have to kill a mouse for every test. Hopefully this can be used more widely in the future.

Thank you for your comment. This method has great potentials and hopefully this will replace the mouse bioassay as the standard of testing.

Well done, Yen! What is the next step in the development of this assay as a readily used test?

Thank you Dr. Keefe. The next step in the development of this assay is to conduct a simultaneous assay system combining an immunoassay for the heavy chain and a fluorogenic enzyme activity assay for the light chain to determine determine potency units of specific pharmaceutical BoNT/A products.

Amazing work, Yen! It will be nice to have a readily available assay in the works that will increase efficiency and save time and resources.

Thanks Angie. This assay has many advantages compared to the the current standard test. It would be great to see this development as the standard test in the future.

Hi Yen, both your poster and research description are very professional. I sent the poster session link to Aiping Wei, so that he can provide some feedback too.

Thank you Dr. Herron